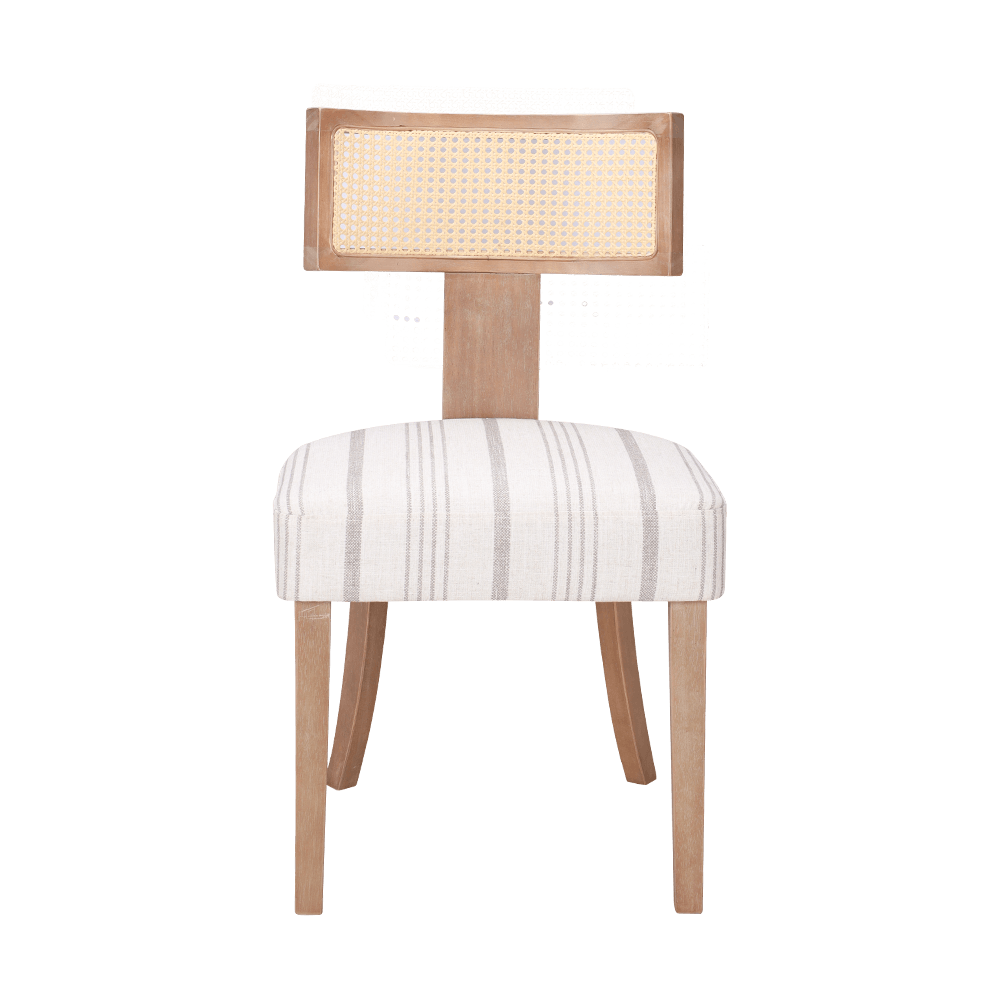

Fabric Lounge Chairs: The Intersection of Comfort, Design, and Material Innovation

Posted by Zhejiang Wanchang Furniture Co., Ltd.

Fabric lounge chairs have evolved beyond basic seating to become sophisticated design elements that blend ergonomic support, aesthetic appeal, and advanced textile technology. Today's premium lounge chairs combine engineered frames with performance fabrics to create pieces that are equally at home in residential interiors, hospitality settings, and commercial spaces.

Content

- 1 Anatomy of a High-Quality Fabric Lounge Chair

- 2 Performance Fabric Technologies

- 3 Ergonomic Design Principles

- 4 Manufacturing Processes

- 5 Commercial vs Residential Specifications

- 6 Sustainability in Lounge Chair Production

- 7 Emerging Trends in Lounge Chair Design

- 8 Maintenance and Care Protocols

- 9 Market Segmentation and Pricing

- 10 Conclusion: The Future of Fabric Lounge Chairs

Anatomy of a High-Quality Fabric Lounge Chair

Structural Components

-

Frame Materials:

-

Hardwood frames (oak, walnut, ash) with mortise-and-tenon joinery

-

Aircraft-grade aluminum with powder coating (indoor/outdoor use)

-

Molded plywood shells (5-9 ply bentwood construction)

-

-

Support Systems:

-

Multi-density foam zoning (3-5 density layers)

-

Suspension webbing (elasticated polyester or natural rubber)

-

Spring systems (no-sag sinuous or eight-way hand-tied)

-

Upholstery Engineering

| Layer | Material Options | Thickness Range |

|---|---|---|

| Top | Performance velvet, bouclé, linen | 0.8-1.5mm |

| Padding | High-resiliency foam, down clusters | 2-5cm |

| Interliner | Non-woven fiber, Dacron® | 3-10mm |

| Base | Twill, canvas, jacquard | 0.5-1.2mm |

Performance Fabric Technologies

Advanced Textile Solutions

-

Stain-resistant treatments: Fluorocarbon-free nanotechnology

-

Antimicrobial fabrics: Silver-ion infused or copper-coated fibers

-

Outdoor performance: Solution-dyed acrylics (UV-resistant)

-

Stretch upholstery: 15-30% elastane content for form-fitting covers

Material Comparison Guide

| Fabric Type | Abrasion Resistance (Wyzenbeek) | Lightfastness | Cleanability |

|---|---|---|---|

| Performance Velvet | 50,000+ cycles | Grade 5 | Spot clean |

| Crypton® | 100,000+ cycles | Grade 6 | Bleach cleanable |

| Sunbrella® | 75,000 cycles | Grade 7 | Hose washable |

| Wool Bouclé | 25,000 cycles | Grade 4 | Professional clean |

Ergonomic Design Principles

Body Support Engineering

-

Seat pitch: 15-20° reclined angle for thigh support

-

Lumbar curve: 5-7cm protrusion at L3 vertebra

-

Armrest height: 20-25cm above seat for elbow support

-

Headrest positioning: 15° forward tilt for neck alignment

Sitting Posture Analysis

-

Hip angle: 95-105° for optimal spinal alignment

-

Seat depth: 40-45cm for average adult proportions

-

Foot clearance: 5-7cm between seat and floor

Manufacturing Processes

Frame Construction

-

CNC machining: ±0.5mm tolerance joinery

-

Steam bending: 100-120°C treatment for curved elements

-

Finishing techniques: Hand-rubbed oil or catalyzed lacquer

Upholstery Techniques

-

Double-stitched seams: 12-14 stitches per inch

-

Channel tufting: 5-7cm spacing for tension distribution

-

Zippered covers: 5-7mm tooth size for durability

Commercial vs Residential Specifications

| Feature | Residential Grade | Commercial Grade |

|---|---|---|

| Frame Warranty | 5 years | 10+ years |

| Fabric Durability | 30,000 cycles | 100,000+ cycles |

| Foam Density | 1.8-2.5 lb/ft³ | 2.8-3.5 lb/ft³ |

| Fire Rating | UFAC Class I | CAL 117 Section E |

Sustainability in Lounge Chair Production

Eco-Friendly Materials

-

Recycled PET fabrics: 20-100% post-consumer content

-

Natural latex foam: FSC-certified rubber tree sources

-

Water-based adhesives: <50g VOC emissions

Circular Design Features

-

Modular construction: Replaceable components

-

Biodegradable fillings: Kapok, hemp, or coconut fiber

-

Take-back programs: 85% material recovery rate

Emerging Trends in Lounge Chair Design

Smart Furniture Integration

-

Posture sensors: Bluetooth-enabled pressure mapping

-

Climate control: Phase-change material upholstery

-

Adjustable firmness: Air cell matrix systems

Advanced Manufacturing

-

3D knitted upholstery: Seamless, customized fits

-

Robotic sewing: ±0.25mm stitch precision

-

Digital printing: Photorealistic fabric patterns

Maintenance and Care Protocols

Fabric Preservation

-

Vacuuming: Weekly with upholstery attachment

-

Spot cleaning: pH-neutral cleaners (5.5-8.5)

-

Professional cleaning: Every 12-18 months

Frame Maintenance

-

Wood conditioning: Biannual oil treatments

-

Hardware checks: Annual bolt torque verification

-

Suspension inspection: Every 2-3 years

Market Segmentation and Pricing

| Tier | Price Range | Key Features |

|---|---|---|

| Entry | $300-800 | Basic fabrics, simple frames |

| Mid | $900-2,500 | Performance fabrics, ergonomic design |

| Premium | $3,000+ | Custom options, advanced materials |

| Contract | $1,500-5,000 | Commercial durability, modularity |

Conclusion: The Future of Fabric Lounge Chairs

Contemporary fabric lounge chairs represent the convergence of traditional craftsmanship and cutting-edge material science. As consumers demand greater personalization, sustainability, and smart features, manufacturers are responding with innovative solutions that maintain comfort while incorporating technological advancements. The next generation of lounge chairs will likely feature adaptive ergonomics, self-cleaning fabrics, and even greater environmental responsibility without compromising the tactile pleasure and visual appeal that make fabric upholstery enduringly popular. Proper selection based on usage patterns, body mechanics, and aesthetic preferences ensures these investment pieces will deliver both immediate comfort and long-term satisfaction.

中文简体

中文简体 English

English